Transfer of thermal energy in the steady state and transient condition is important in almost every technology and manufacturing process. Heat transfer occurs due to conduction, convection or radiation but transfer of energy may also occur as a result of phase changes or chemical reaction. To develop a full description of thermal transfer in complex components and processes the governing equations of heat transfer are integrated with finite element analyses procedures. Heat transfer due to conduction in solids is described by:

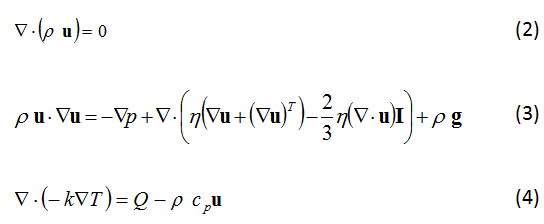

Convective heat transfer in a fluid at a non-uniform temperature creates flow due to the variation in density and the action of gravity. Advanced analyses couple the fluid and thermal response using the conservation of mass, momentum, and energy equations:

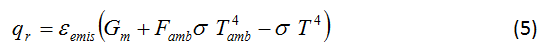

This approach allows accurate analyses of natural and forced convection. Radiation heat flux at the surface is described by:

And mutually irradiating surfaces are accounted for by ambient view factors and mutual irradiation.

AltaSim Technologies has solved heat transfer analysis problems resulting from a combination of these mechanisms in the solid, liquid and gas phases, and the effect of interactions between them.

With our experience in Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) we can analyze complex, coupled heat transfer problems and their effect on real world products and processes. Among the areas in which we have applied our expertise in heat transfer are:

- Solid-liquid-gas phase change

- Chemical reaction enthalpy

- Heat transfer due to combined conduction, convection and radiation

- Conjugate heat transfer due to forced fluid flow

- Bio heat problems

- Heating induced by electric fields (Joule heating)

- Heating of metal, polymer and bio-materials

By teaming with AltaSim Technologies, our customers understand the heat transfer characteristics of applications ranging from small scale microelectronics circuits to large scale chemical processing plants allowing them to:

- Develop manufacturing processes with optimum transient and state distributions of thermal energy

- Predict the thermal history of products subject to forced cooling

- Define thermal gradients developed in human tissue

- Design cooling systems to produce a known thermal history

- Predict the influence of phase changes on heat evolution and dissipation

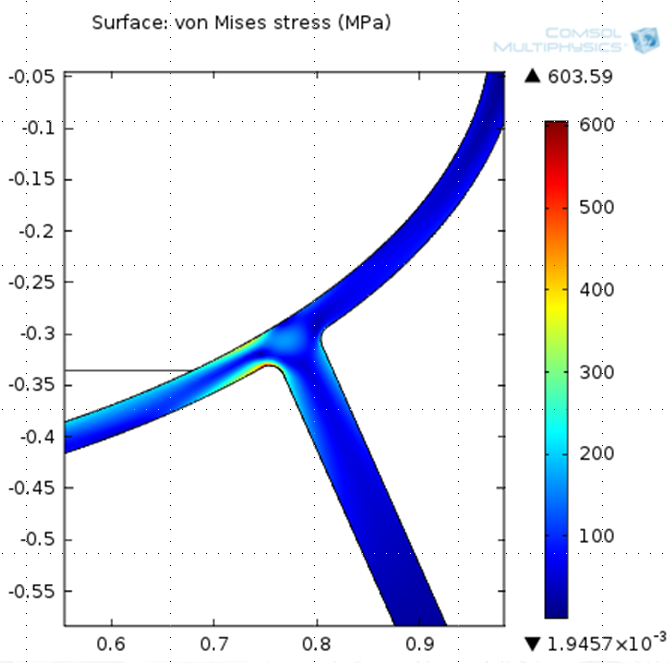

Continuously cycling through large temperature ranges can induce thermal expansion that may cause problems such as distortion, residual stresses and thermally induced failure. Our experience of heat transfer and structural analysis allows us to perform multi-disciplinary analyses to predict the influence of thermal loading on the component failure for small and large scale components. As a result potential catastrophic component failure has been alleviated and maintenance schedules developed to monitor at risk operations.

In addition, AltaSim also provides a comprehensive range of training on heat transfer solutions with the following course:

Heat Transfer - Stress Analysis

Recent Blog Posts on Heat Transfer

Need Help with Heat Transfer Analysis?

Contact us about our Heat Transfer technology services.