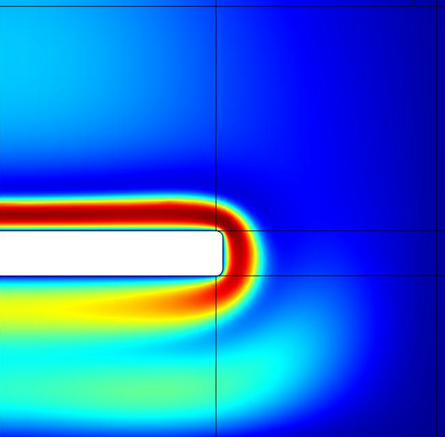

A plasma is a collection of electrons, ions, and neutral atoms or molecules in a gaseous state. For most industrial applications the fraction of atoms or molecules ionized is typically less than one percent, but this is sufficient to transform a gas into a highly conductive medium that interacts with applied electric or magnetic fields. Plasmas generally exhibit strongly coupled interaction between electron transport, ion transport, chemical reactions, electromagnetic fields, heat transfer, and fluid flow – a truly multiphysics phenomenon.

The unique electrical, chemical, thermal and radiative properties of plasmas make them useful for many applications. Accordingly, they are utilized extensively in a variety of industries, including electronics manufacturing, lighting, materials analysis, lasers, and space propulsion. Due to the complexity of plasma physics, the development of plasma-based technologies can present formidable engineering challenges. Intuition and experience are often insufficient to predict plasma behavior to the desired level of accuracy and detailed experimental characterization of plasmas is typically difficult due to the extreme operating conditions. For these reasons, computational models that can provide insight into the plasma dynamics and quantify the effects of design changes are valuable to understand factors such as plasma deposition rates, breakdown potential and device designs for plasma formation.

As one might expect, the complexities of plasma physics present considerable impediments to the development of computational plasma physics models. The numerous chemical species and reactions, the often incomplete physical data for many species and the highly non-linear behavior of plasmas are a few of the difficulties associated with plasma modeling. Until recently, the challenges of plasma simulation generally restricted analysis to models with limited spatial variation or heavily simplified chemistries, but advances in both computational power and numerical techniques have enabled simulation of many plasma applications with much greater complexity. As a result, computational modeling has been increasingly employed in the design of a variety of plasma-based technologies.

In plasma modeling, two approaches are typically used to simulate the transport of electrons, ions, and neutral species: kinetic or fluid. In the kinetic description each species in a plasma model is treated as either a collection of particles with various velocities; in a fluid description a continuous medium characterized by macroscopic quantities such as density and temperature is used. The kinetic and fluid descriptions are sometimes used together, where some species are described using a kinetic approach and others are described by a fluid approach.

When a kinetic description of a species is used, it is usually neither possible nor desirable to track the position and velocity of every particle of that species. Rather, a representative distribution of the particle positions and velocities is sought. One manner of accomplishing this involves explicitly tracking the location and velocity of many discrete “macro-particles,” with each macro-particle representing a large number of particles of that species. Another approach entails solving a kinetic equation (e.g. the Boltzmann or Vlasov equation) for an average distribution function, which is a continuous function describing the velocity distribution of the species at every point in space. Kinetic descriptions of the plasma species generally offer the potential for highest accuracy, but in many applications the computational requirements can quickly become prohibitive.

A fluid description of a plasma species tends to be less computationally intensive than a kinetic description and it is also more suitable for incorporating chemical reactions. These advantages, however, come with a significant drawback: an energy distribution function must be assumed. While this is often not an important consideration for ions and neutral species, it is significant for electrons. The electron energy distribution function (EEDF) has a substantial impact on the plasma characteristics, and the EEDF is itself highly dependent on the operating conditions and composition of the plasma. To account for the effects of a non-Maxwellian EEDF, a simplified form of the Boltzmann equation is solved and the results of the analysis generate the transport coefficients and reaction rates to define the fluid equations. In this way, a simplified kinetic description of the electrons is implicitly incorporated in the fluid description without substantially increasing the computational requirements, generally this provides sufficient accuracy for most plasma applications.

The kinetic and fluid approaches can be adapted and combined in various ways to construct a plasma model. For normal industrial plasmas, kinetic descriptions of ions and neutrals do not typically provide enough advantage to justify the computational cost, so purely kinetic plasma models are seldom used. Instead, a kinetic description of the electrons, and possibly high energy ions and neutrals, can be combined with fluid descriptions of the remaining species. This type of hybrid plasma model has the potential for high accuracy in a broad range of applications by exploiting the strengths of both kinetic and fluid approaches, but it remains quite computationally intensive. Plasma models utilizing only a fluid approach include multi-fluid and magnetohydrodynamic (MHD) models; multi-fluid models treat all species as separate, interpenetrating fluids, and typically utilize a Boltzmann solver as a preprocessing step. This type of plasma model can provide sufficient accuracy for most industrial plasmas while maintaining reasonable computational requirements and thus it is widely used. In contrast, MHD models treat the plasma as a single electrically conductive fluid, potentially resulting in lower computational requirements but also restricting the range of applications for which the model is suitable.

Integration of these approaches for computational analysis of plasma phenomena into the early stage of plasma product and technology design has allowed AltaSim to assist our clients achieve optimum performance in a range of plasma technologies such as:

- DC

- Inductively coupled plasma

- Capacitively coupled plasma

- Microwave plasma excitation

When coupled with GUI designed for use by non-experts, computational analyses of plasma can be structured to provide process engineers the opportunity to use computational analysis to troubleshoot current problems and design improved processes and technologies.

Need Help with Plasma Modeling?

Contact us about our Plasma Modeling technology services.